Rourkela: The Karmaveer Quality Circle team from coke ovens department of SAIL’s Rourkela Steel Plant has brought about substantial savings for the company apart from enhancing the safety and efficiency of operations in Battery-6. Notably, Battery-6 houses 67 state-of-the-art 7-metre-tall ovens that make 0.9 million tonne coke annually. There was a critical concern in the CDCP unit of coke ovens, where mill-fan failures during the dry quenching process led to a halt in fuel gas circulation, risking coke combustion and potential explosions that could damage chamber lids and walls. The existing hydraulic system was insufficient for opening the cooling chamber lids under these conditions, posing serious operational challenges.

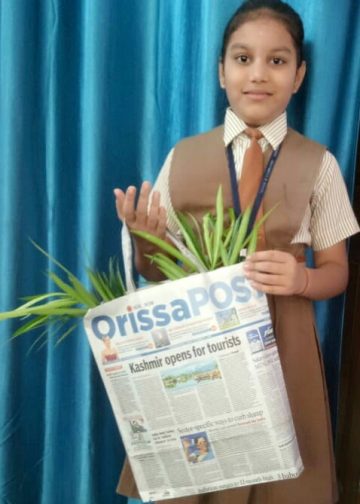

The QC team comprising Sanjay Kumar Sahoo, senior technician, Hadibandhu Sahoo, Aswini Kumar Behera, and Deepak Kumar Dey, operators, under the guidance of Kulamani Sahoo, technician and B Panda, senior manager, coke ovens addressed the issue and implemented a crucial modification in the hydraulic system by adding an additional accumulator. This innovative solution not only enhanced operational safety but also maximised pushing in Battery-6 and cooling cycles in the CDCP unit, leading to a substantial saving of `2.7 crore annually. The enhancement ensured the exertion of sufficient hydraulic pressure, allowing for easier lid opening during mill fan failures, thereby preventing coke burning and explosions. The team’s exemplary efforts earned them the prestigious Gold Award at the plant-level quality circle competition.