SN Misra

Industry 4.0, the latest buzzword both in developed and developing economies, is the application of high-end technology like AI, robotics, and cloud computing in manufacturing. From the discovery of steam engine in 18th century (Industry 1.0) to adoption of mass production through electrical energy (Industry 2.0) to the advent of computer and electronics in the 1960s (Industry 3.0), to Industry 4.0, particularly in the automotive sector since 2011, Germany has been the pioneer. India has been a babe in adapting to this march of technology, given its dual economy in manufacturing and the huge digital divide that plagues particularly the unorganised segment and the fledgling MSMEs. The Union Finance Minister in her Budget speech 2021 underlined the importance of harnessing the humongous benefits that flow out of adopting Industry 4.0 in terms of efficiency and economies of scale, but made a token allocation.

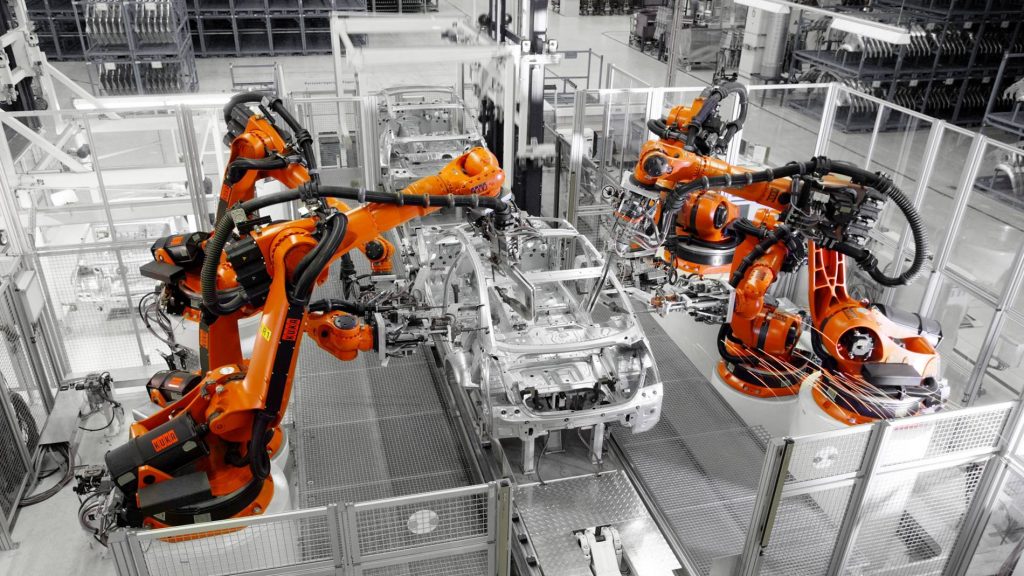

Manufacturing has been the prime beneficiary of Industry 4.0 and the automotive sector has been the prime sub-sector which has witnessed significant technological changes. Industry 4.0 is breaking silos between design, manufacturing, sales and marketing and service support. Sadly, manufacturing has been the bane of the Indian economy since 1951 with a stagnant contribution of 16% to the GDP. This is in sharp contrast to manufacturing powerhouses like Germany, China and Japan where the share of manufacturing is close to 36% of GDP. India’s growth story has skipped manufacturing sector and moved from primary to service sector which contributes 58% of GDP.

Taking note of this concern, V Krishnamurty, as Chairman of National Manufacturing Policy 2011, had recommended that India needs to increase its manufacturing footprint from 16% to 25% by 2022 by creating and galvanising manufacturing zones. The fond hope was that it will create additional employment of nearly 10 million per year. The reality is that after a decade, India has failed to achieve these targets. Since the service sector does not create significant employment opportunity, India’s high growth story of more than 8% per year during 2004-2010 has been largely jobless!

MSMEs have been at the forefront of India’s manufacturing story, employing nearly 111 million people and contributing 45% to total manufacturing output, 40% of exports and 30% of GDP. As per the Labour Bureau Report 2016, only 14% of the workforce is either highly or moderately skilled while the balance 84% is either unskilled or low skilled. This is indeed a humongous challenge.

Some of the initiatives that the government has taken for embracing Industry 4.0 are creation of Digital India Corporation, Cyber Physical Laboratory, Cyber Physical Factory and the ambitious programme called Samarth (Smart Advanced Manufacturing and Rapid Transformation Hub). Andhra Pradesh is a pioneer in setting up IoT (Internet of Things) hubs and it hopes to gobble up 20% of global demand for IoT. A machine-to-machine communication centre has been established at the Indian Institute of Science, Bangalore. Most of the beneficiaries of Industry 4.0 in India are in the automotive sector which has witnessed three clusters in Chennai, Pune and the North. Bajaj Auto uses cobots (collaborative robots) in production. Maruti Suzuki has replaced 10,000 workers with robots. Both Hyundai and Tata are also using robots.

However, the MSMEs are hugely handicapped in terms of adopting Industry 4.0. The CII has brought out how Industry 3.0 (use of computer and electronics) has still not been entirely implemented throughout the manufacturing sector. The MSMEs are still in post electrification phase. For adopting Industry 4.0, Network Readiness Index is a critical parameter. As per the latest report, Singapore is the leader followed by USA and German (Rank 5, 6). China holds the rank of 59 and India 91 despite the enormous IT resource it possesses.

Investment in R&D has been a critical component for achieving increasing returns to scale after the 1950s. India’s record in R&D spending is dismal at 0.7% of GDP unlike around 3% spent by developed economies like USA, Germany and Japan. China invests close to 2.2% of GDP and in absolute number it spends close to $ 600 billion as against $ 90 billion in India. A lesson India can draw from countries that have successfully adopted Industry 4.0 is including AI as part of curriculum in educational institutions and vocational training institutions.

The famous biologist EO Wilson has observed that “we have stumbled into 21st century with stone age emotion, mediaeval institution and god like technology.” For Industry 4.0 to succeed, India has to invest more in R&D and bridge the digital gap that divides bulk of the MSMEs from large industrial houses. The pandemic has shown how the digital divide has been further widened, particularly in online education. If India wants to harness demographic dividend it has to up its antenna in public sector investment in quality education, healthcare, sanitation and skill. Tokenism in allocation and rhetoric of Atmanirbhar Bharat must give way to pragmatism and global collaboration. Prof Rosenstein-Rodan had recommended (1943) Big Push for underdeveloped countries to come out of the poverty trap and achieve high growth. The manufacturing sector & MSMEs must come out of the morass of low technology trap to harness the full benefit of Industry 4.0.

The writer is Dean, School of Management, KIIT Deemed to be University. Views are personal.